Imagine walking into a factory where robots are not just machines but intelligent partners working alongside humans. This is not a scene from a sci-fi movie; it’s the reality of today’s manufacturing landscape, thanks to the rise of AI-driven robotics. As we delve into this fascinating topic, let’s explore how these technologies are reshaping manufacturing processes, enhancing productivity, and what this means for the future of work.

The Evolution of Robotics in Manufacturing

For decades, robotics has played a pivotal role in manufacturing, primarily focused on automating repetitive tasks. However, the integration of artificial intelligence (AI) has ushered in a new era—one where robots can learn, adapt, and collaborate with human workers. Have you ever wondered how this shift impacts the assembly line and precision tasks?

– Learning and Adaptation: AI enables robots to learn from their environment and improve their performance over time. This means they can handle more complex tasks that were previously thought impossible for machines.

– Data-Driven Decisions: With AI, robots can process vast amounts of data to optimize workflows and make real-time decisions. This capability enhances efficiency and reduces errors.

From Automotive to Electronics let us take a closer look at some of the real-world applications and compelling examples of how AI-driven robotics are transforming various sectors within manufacturing:

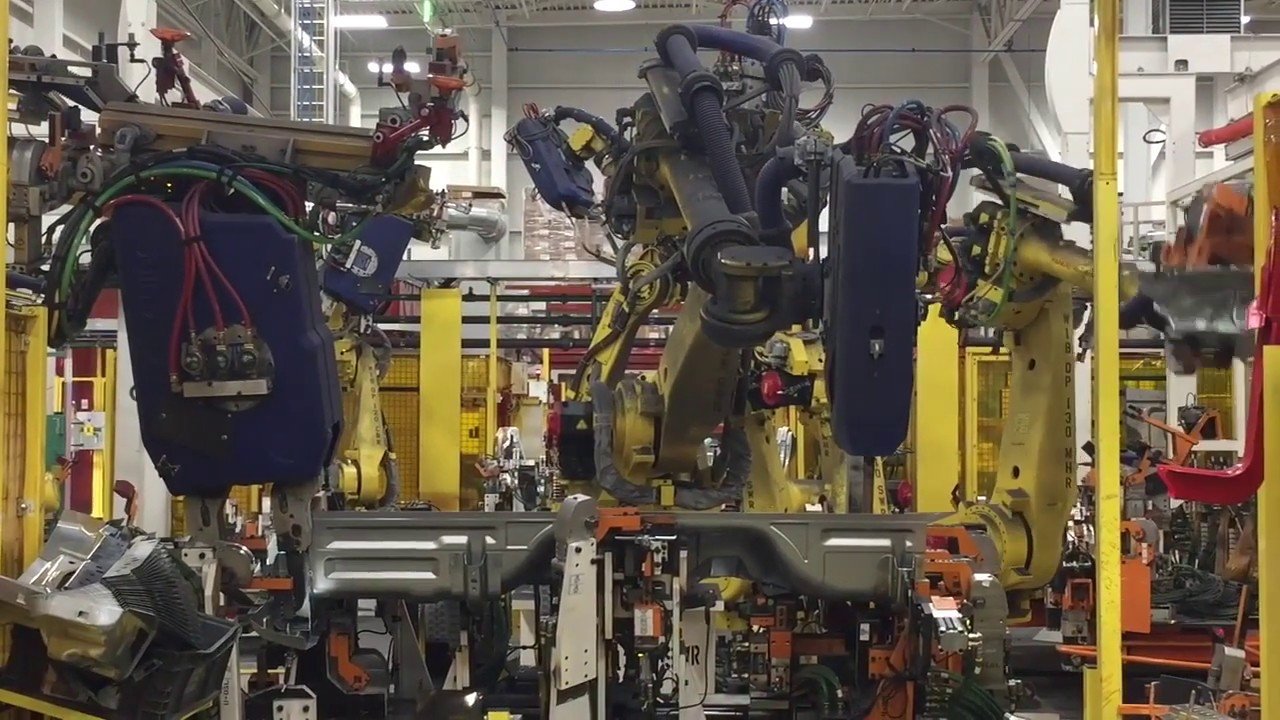

1. Automotive Industry:

In automotive manufacturing, robots equipped with AI are revolutionizing tasks like painting and welding. These robots can adjust to different car models without needing extensive reprogramming. Imagine a robot that can seamlessly switch from assembling a sedan to an SUV—this flexibility boosts production speed and quality. AI has played a crucial role in the development of autonomous vehicles as well, enabling them to navigate and operate without human intervention.

- Nissan: At Nissan’s Oppama plant, Automated Guided Vehicles (AGVs) are employed to transport assembly parts directly to workers. This system reduces the need for manual material handling, allowing workers to concentrate on more complex tasks. The integration of AGVs has led to improved efficiency and safety on the production line, showcasing how robotics can streamline operations while enhancing worker productivity.

- Tesla: Tesla has pioneered the use of AI in its manufacturing processes through its Gigafactories. These facilities utilize advanced AI algorithms for predictive maintenance, optimizing production processes, and automating complex assembly tasks. This approach not only speeds up production but also ensures high precision and quality control in manufacturing electric vehicles.

- Ford: Ford has implemented vision-guided robotics in their manufacturing processes, allowing robots to perform tasks such as bin picking and assembly with high accuracy. This technology enhances productivity by reducing errors and increasing the speed of operations on the assembly line.

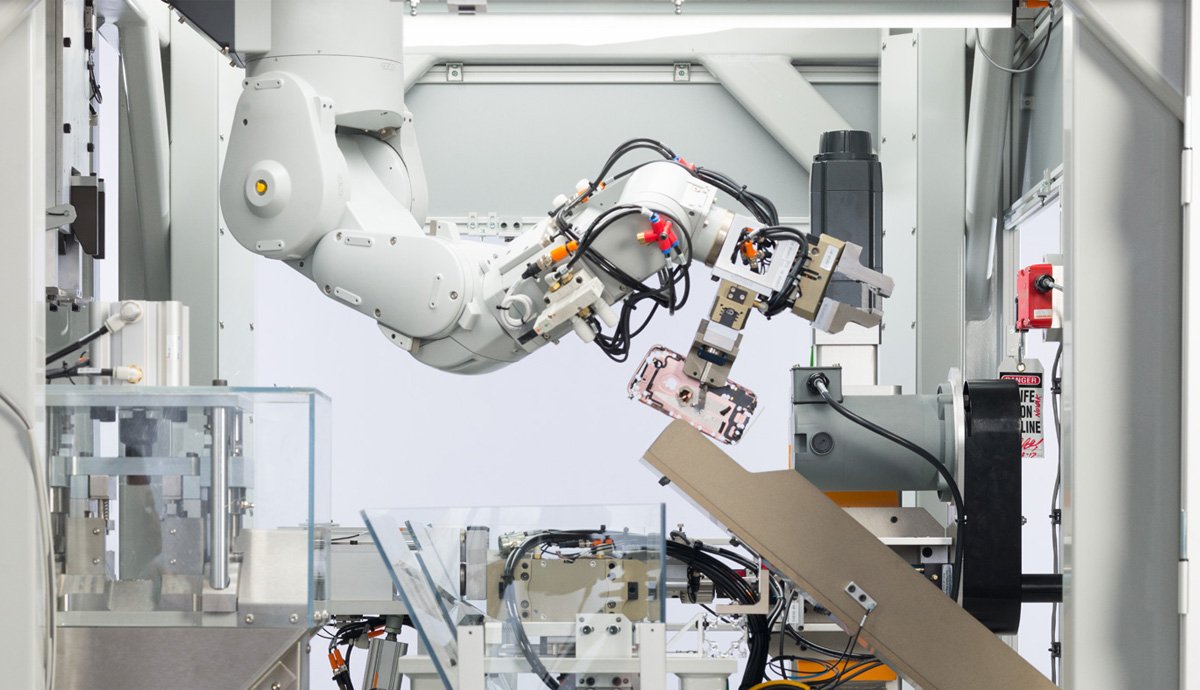

2. Electronics Manufacturing:

The electronics sector relies heavily on precision. AI-powered robots are crucial for assembling intricate components, such as circuit boards. Their ability to work with millimeter precision significantly reduces errors and increases output. Have you ever thought about how your smartphone is produced? It’s likely that AI-driven robots played a key role in its assembly.

- Samsung: Ballie robot by Samsung is a companion is designed to enhance everyday life and is set to launch in the first half of 2025. Ballie will feature new Vision AI functionalities that allow it to navigate homes and interact with users seamlessly. This cheerful yellow robot is equipped with a front projector for displaying information and entertainment, as well as multiple sensors and cameras for enhanced interaction. Its ability to control smart home devices and respond to voice commands makes it a versatile assistant, capable of providing personalized support while maintaining high standards of functionality and user engagement.

- Apple: Utilizes robots for assembling components like iPhones. These robots are equipped with computer vision systems that allow them to identify and manipulate small parts with great accuracy. This automation not only speeds up the assembly process but also reduces the likelihood of defects.

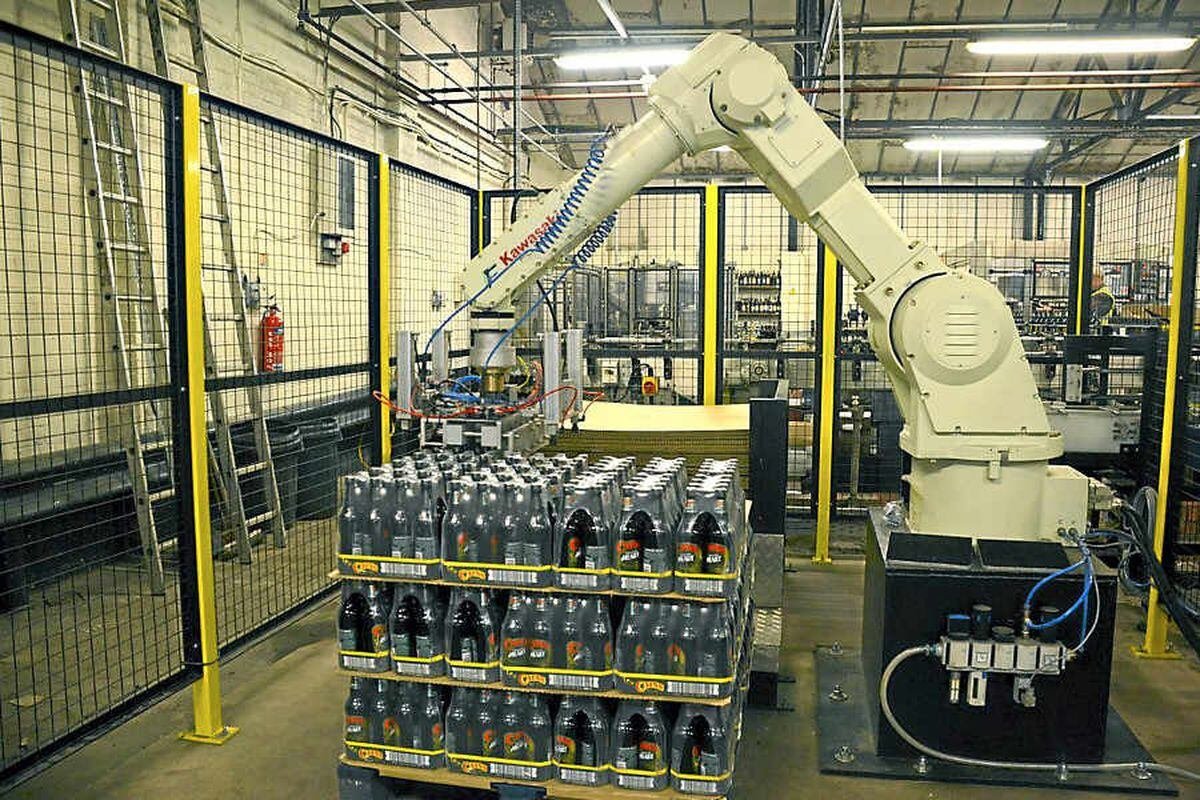

3. Small and Medium Enterprises (SMEs):

SMEs are also reaping the benefits of AI robotics. By integrating these technologies, smaller manufacturers have seen marked improvements in efficiency and product quality. This integration provides them with a competitive edge in a crowded market.

- Flex-N-Gate: Flex-N-Gate, a supplier for the automotive industry, has integrated AI-driven robotics into its production lines. By automating various tasks, the company has improved operational efficiency and reduced labor costs, enabling it to compete effectively against larger manufacturers.

- Local Craft Breweries: Many small craft breweries are adopting robotics for bottling and packaging processes. By using automated systems for these repetitive tasks, they can focus on brewing quality beers while ensuring consistent packaging standards.

The Impact on Productivity

Now that we’ve seen how various industries are adopting AI-driven robotics, let’s discuss their impact on productivity.

– Increased Efficiency: Robots can work continuously without fatigue, performing repetitive tasks that would be exhausting for human workers.

– Reduced Labor Costs: By minimizing the need for manual labor in certain areas, companies can lower their overall production costs.

– Enhanced Quality Control: With AI’s data analysis capabilities, robots can detect defects in real-time, ensuring higher quality products reach consumers.

A notable example of the impact of AI-driven robotics on productivity can be seen in General Motors. GM has integrated FANUC robotics into their production lines to automate strenuous processes such as plug insertion and painting. This automation has resulted in a significant increase in productivity—by reducing labor needs and minimizing waste, GM has enhanced its overall operational efficiency. The implementation of these robotic systems allows GM to maintain high-quality standards while meeting production demands more effectively.

Challenges and Considerations

While the benefits are significant, there are challenges that manufacturers must navigate as they adopt these technologies:

– Workforce Transition: As robots take over more tasks, what happens to human workers? It’s essential to foster a culture of continuous learning where employees can upskill and adapt to new roles that focus on creativity and strategic thinking.

– Building Trust: For successful integration of AI-driven robotics, manufacturers must establish trust between human workers and machines. This involves training employees to work alongside robots effectively.

The Future of Manufacturing: A Collaborative Ecosystem

Looking ahead, what does the future hold for manufacturing with AI-driven robotics? Experts suggest that we will see even greater interconnectivity between machines and data systems. Imagine a factory where machines communicate with one another—alerting each other about maintenance needs or production schedules in real-time.

This collaborative ecosystem could lead to:

– Smart Factories: Fully automated environments where AI manages production schedules based on demand forecasts.

– Enhanced Human-Robot Collaboration: Workers focusing on high-value tasks while robots handle repetitive or dangerous jobs.

Conclusion

The transformation brought about by AI-driven robotics is profound and far-reaching. From enhancing productivity to reshaping workforce dynamics, these technologies are not just changing how we manufacture products—they’re redefining the very nature of work itself. As we move forward into this new era, embracing innovation while addressing challenges will be key to harnessing the full potential of robotics in manufacturing.

So next time you see a robot on an assembly line or hear about AI innovations, think about the exciting possibilities they bring—not just for businesses but for all of us as we navigate this evolving landscape together.